Cognitive Predictive Maintenance

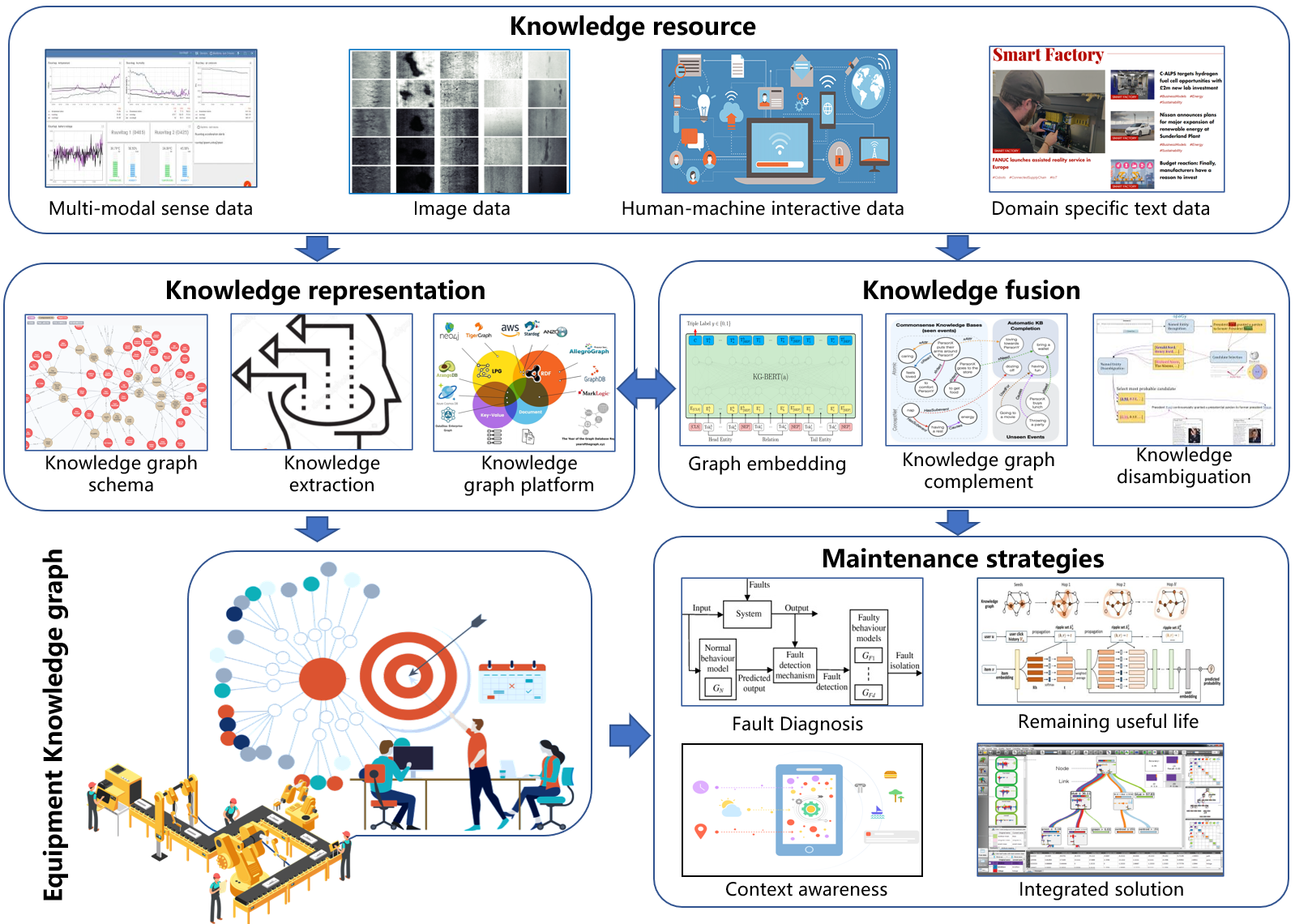

Nowadays, conventional physics-based or data-driven Prognostics and Health Management (PHM) approaches alone fail to satisfy the diversified demand for complex equipment predictive maintenance. To address it, the Industrial Knowledge graph (IKG) and graph embedding (e.g. graph convolutional network) techniques have shown promising prospects in gathering and merging multiphysics-based information, as well as offering extendable representation and explainable reasoning of multi-disciplinary domain experience and knowledge in a data-driven context-based manner. Therefore, representing complex equipment in the IKG form can organize complex equipment in a graphic and logical manner, and conduct explainable querying for generating the optimal predictive maintenance strategies.

The IKG of complex equipment enables the generation of integrated strategies, including fault diagnosis, optimum maintenance plan, manual maintenance guidance, remaining useful life prediction, etc. Meanwhile, the visual equipment knowledge graph provides explanation for the integrated solutions. Furthermore, in the manufacturing process, the equipment knowledge graph is context-aware and interactive, which can adopt timely and effective reactions during the user interface and unexpected intervene, such as warning, adjustment, and recommendation.

Funded Projects

- 12/2023 – 11/2025 ‘基于自主学习的沉浸式自动化制孔在线质量评估’, 國際合作預先研究科研項目, 中國商飛上海飛機製造有限公司, PI

- 01/2023 – 12/2025 ‘Research on key technologies of cognitive predictive maintenance of complex equipment based on domain knowledge graph’ (2023A1515011557), Department of Science and Technology of Guangdong Province (GDSTC) 廣東省科學技術廳面上項目, PI

- 07/2021 – 06/2023 ‘Industrial big data-enabled smart maintenance technology for complex equipment’ (MHX/001/20), Mainland Hong Kong Joint Funding Scheme (MHKJFS), by Innovation and Technology Commission (ITC), HKSAR & Ministry of Science and Technology (MOST), China, HK$2,826,700 (Total amount: ~HK$6 Million), Hong Kong PI (Mainland Partner: CasiCloud Inc.)